Multi-Post Rig

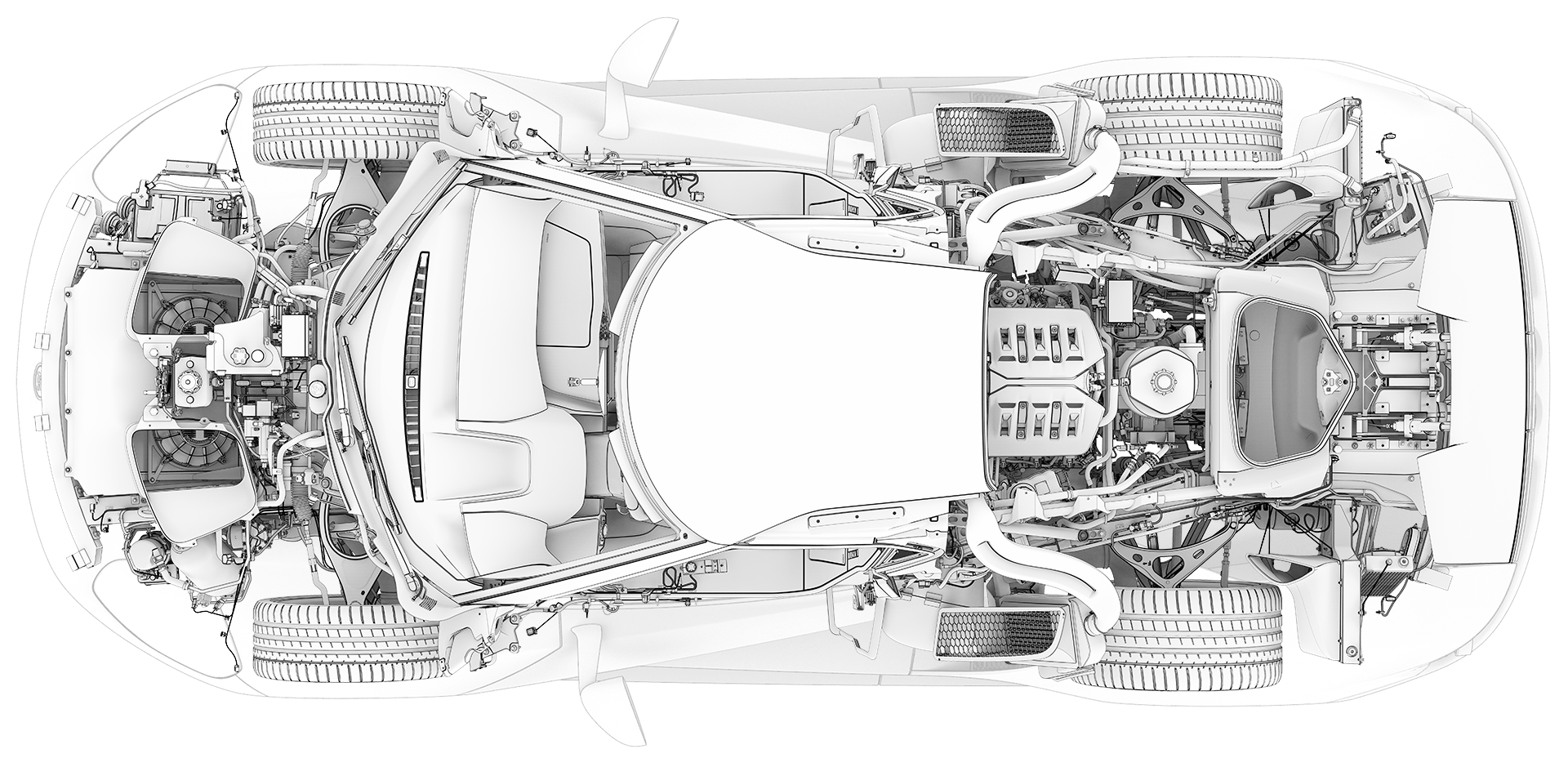

Optimise performance with Multimatic’s multi-post test rig. It facilitates a deep understanding of your vehicle’s vertical dynamics so you can explore tuning options.

The Multimatic multi-post rig is one of the busiest rigs in the UK. It is used across the spectrum of motorsport, from Formula Student to Formula ONE™ and by OEMs across Europe. The rig was developed in-house using Multimatic’s own proprietary hardware, control systems and analytical software. It was created and is run by experienced motorsport and major OEM engineers. These engineers can take you through the test and conduct further analysis.

Evaluation & Analysis of Vehicle Conditions

Dampers

Optimising damping stiffnesses for motorsport applications to improve load control, ride height variation, hub and body phasing between axles and quantifying the effect on the dynamic roll distribution of the vehicle.

For automotive applications the optimisation procedure focuses on primary and secondary modes to study the effect on comfort and vehicle handling response, as indicated by the customers vehicle specification.

Both optimisation procedures include characterising all elements of the damper including:

- Hysteresis

- Force vs velocity relationship

- Bump and rebound biasing

Modal Evaluation to Study Vehicle Behaviour

Multi-Post Rig Testing

What we measure

- Tyre stiffness

- Wheel rates

- Damper tuning

- Contact patch load variation

- Ride height control

- Hub and body phasing

- Cost function known as “Performance Index”

- Comfort

- Vehicle symmetry

- Axle Natural Frequencies and damping ratios

- Heave and Pitch Natural Frequencies and damping ratios

- Sprung Mass Modal Evaluation

Why

- Provides estimates of vehicle properties

- Identifies sources of vehicle deficiencies

- Quantifies effects on suspension performance

- Optimising springs, dampers and tyres

- Characterising different suspension systems

- Reviewing previous and existing vehicle setups

How we do the tests

Modal analysis

- Heave

- Pitch

Quasi-static warp

- Roll stiffness evaluation

Kerb strike analysis

- Wheel and body disturbance

- Contact patch load variations

- Static and dynamic roll distribution

Results

Detailed graphical reports summarising results:

- Heave summary table

- Kerb strike summary table

- Frequency response plots

- Time domain analysis plots

- Roll stiffness summary table

- Nomenclature

- General note and guide on data

Multimatic staff on hand to guide customers through results obtained

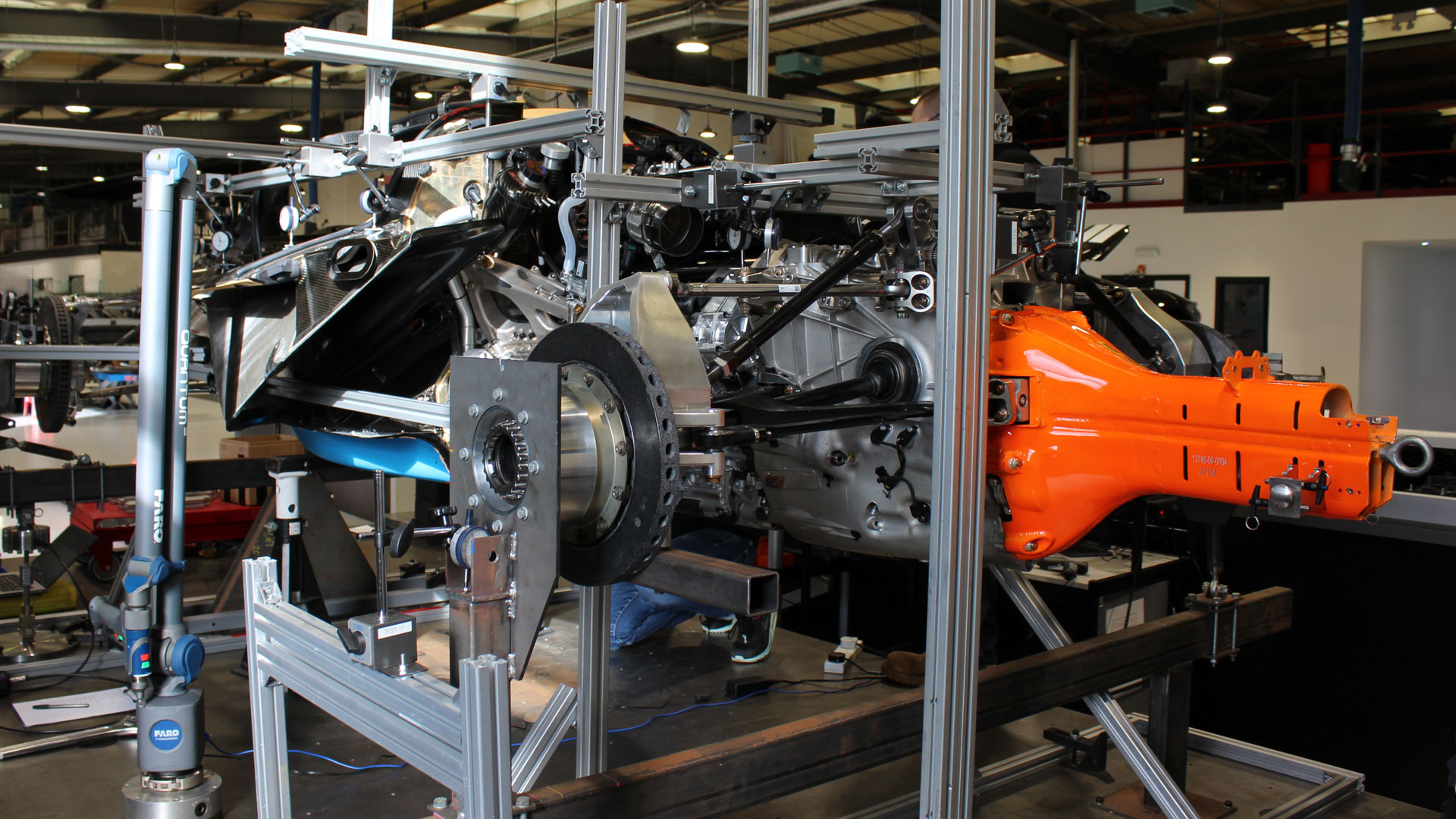

Bending and torsional testing

Multimatic offers bending and torsional testing services for standalone monocoque chassis as well as partial or complete vehicles, accommodating both hub-to-hub and bulkhead-to-hub setups. Please contact us to discuss your exact requirements and desired configurations.

Common Questions

What is the Multimatic multi-post test rig and what does it do?

- The Multimatic multi-post test rig is a tool used for tuning and optimisation of road and race vehicles as a sprung mass damper system.

- Vehicle set-up and optimisation is performed by analysing the vehicle’s response to a vertical heave input. This analysis allows Multimatic’s engineers to create a linear vehicle model and in turn suggest changes to the vehicle to improve its response.

- To generate the vehicle model Multimatic utilises proprietary software that was developed internally by Dave Williams. A large number of parameters are produced from a single heave run such as contact patch load variation, damping ratios, dynamic ride height change and tyre deflection with all of the metrics being summarised into one single number known as a ‘Performance Index’.

- The aim of the test is to improve the vehicles overall ‘Performance Index’ as the day progresses.

- Our primary vehicle dynamics facilities are located in Thetford, England (UK), Markham, Ontario (Canada) and Novi, Michigan (USA).

Is the Multimatic multi-post test rig a 7-post rig?

Which test inputs do you use? Do you do Heave and Pitch input?

What is the length of a single test run?

Each run is approximately 30 seconds in duration.