Kinematics & Compliance Rig

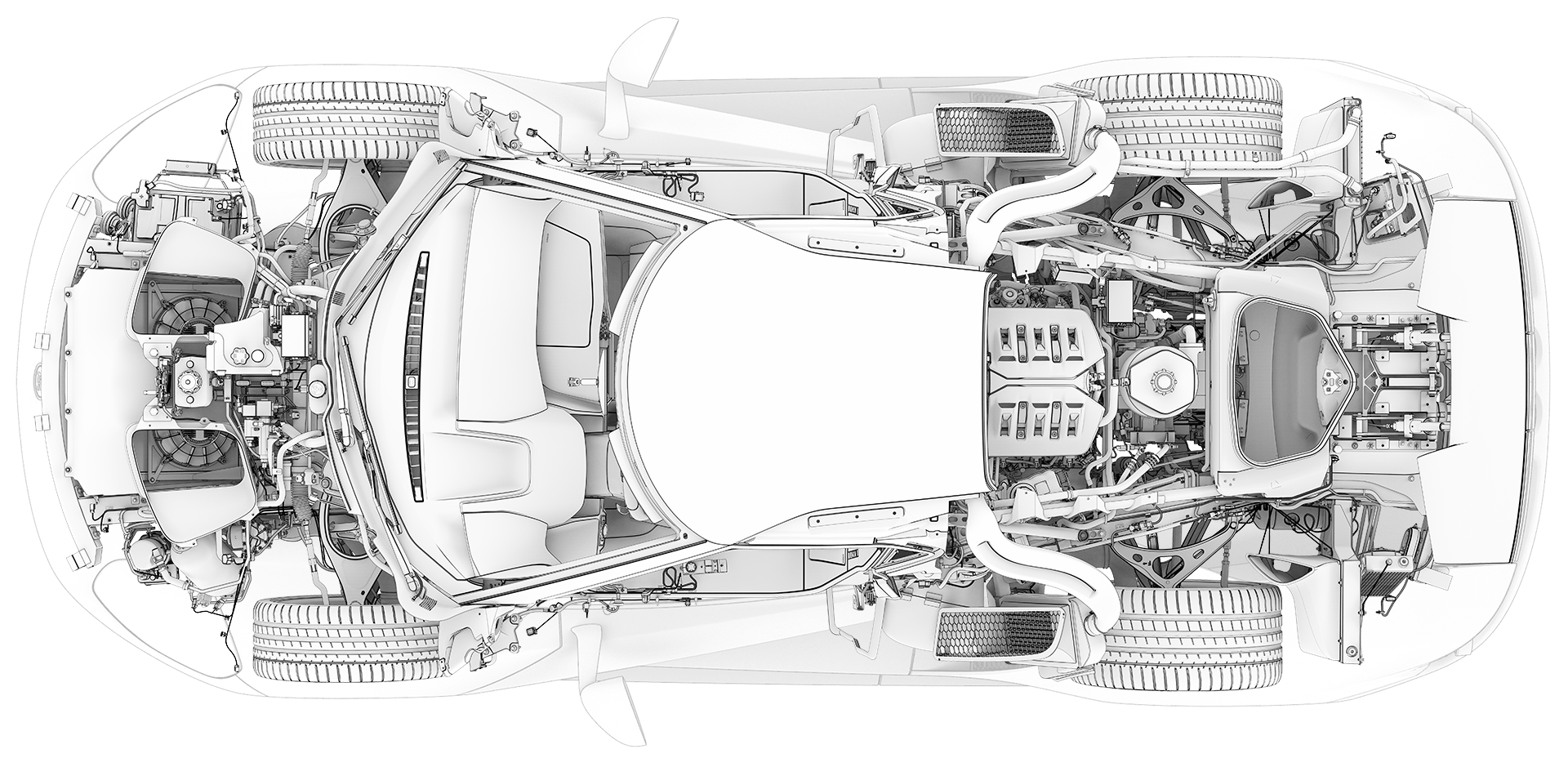

The Kinematics & Compliance (K&C) rig subjects a vehicle to quasi-static tests by applying desired loads and displacements to determine suspension geometry and stiffness characteristics.

The SPMM 4000, manufactured by Anthony Best Dynamics, has a moving centre table that is accurately controlled with five degrees of freedom. This allows the combination of roll, pitch and heave to be applied to the vehicle. By constraining the vehicle body in this manner, it allows the ground plane (road) to remain fixed and accurately measure vehicle cornering and braking simulations.

The SPMM 4000 is configured with four wheel stations, which apply X, Y and Delta displacements to each wheel and measure the resulting forces. The six string encoders per corner then measure the resulting X, Y, Z, steer, camber and spin displacements to a resolution of 10 microns.

Multimatic guides customers through a K&C test, by ensuring constant communication and detailed explanations of results.

Point of interest clicker and graphic

Suspension Kinematics

Suspension kinematics refer to the movement of the suspension without load applied. Understanding how the alignment of a vehicle’s wheels change during suspension movement is key to understanding the handling properties of the vehicle. Mapping the kinematics of a vehicle also enables validation against the intended design kinematics.

Evaluation of

Measurement of the articulation of a vehicle’s wheels due to the geometry of its suspension

What

- Motion ratios

- Wheel rates

- Roll bar rates

- Camber gains

- Caster

- Friction

- Roll centres (kinematic & force based)

- Anti-dive

- Anti-squat

- Anti-lift

Why

- A complete understanding of the vehicle’s kinematic and compliance properties

- Quasi-static simulation validation

- Evaluate vehicle against design targets

- Comparing performance of differing suspension components

- Benchmark competitor vehicles

How

- Vertical bounce

- Vertical bounce with pitch

- Roll fixed axis

- Roll constant axle load

- Steering geometry

Results

- Detailed graphical report summarising results

- Multimatic staff on hand to guide customers through results obtained

- All raw data from tests

Measurement of the deflection, under load, of a vehicle’s wheels (reflecting the stiffness of its various metallic and elastomeric suspension components)

What

- Toe compliance

- Camber compliance

- Wheel centre compliance

- Subframe compliance

- Steering rack compliance

Why

- A complete understanding of the vehicle’s kinematic and compliance properties

- Quasi-static simulation validation

- Evaluate vehicle against design targets

- Comparing performance of differing suspension components

- Benchmark competitor vehicles

How

Compliance tests available:

- Lateral in-phase

- Lateral anti-phase

- Longitudinal braking & acceleration

- Longitudinal braking & acceleration (LHS only)

- Longitudinal braking & acceleration (RHS only)

- Single axle acceleration test

- Aligning torque in-phase

- Aligning torque anti-phase

- Bounce at constant lateral load

- Bounce at constant longitudinal load

Results

- Detailed graphical report summarising results

- Multimatic staff on hand to guide customers through results obtained

- All raw data from tests

Common Questions

How long does a standard K&C test take?

What is the length of a single test run?

What are the rig operation hours?

Which tests are you able to conduct?

The most common tests include:

- Kinematic Tests: Bounce, Bounce with Pitch, Roll, Steering.

- Compliance Tests: Longitudinal, Lateral (in phase, anti-phase), Aligning Torque (in phase, anti-phase).