World-Class Vehicle Dynamics

Expertise

With expertise in all of the VDC facilities, in addition to real world testing, Multimatic’s engineers can ensure continuity for your development project by supporting your testing across all areas of the facility.

Facilities

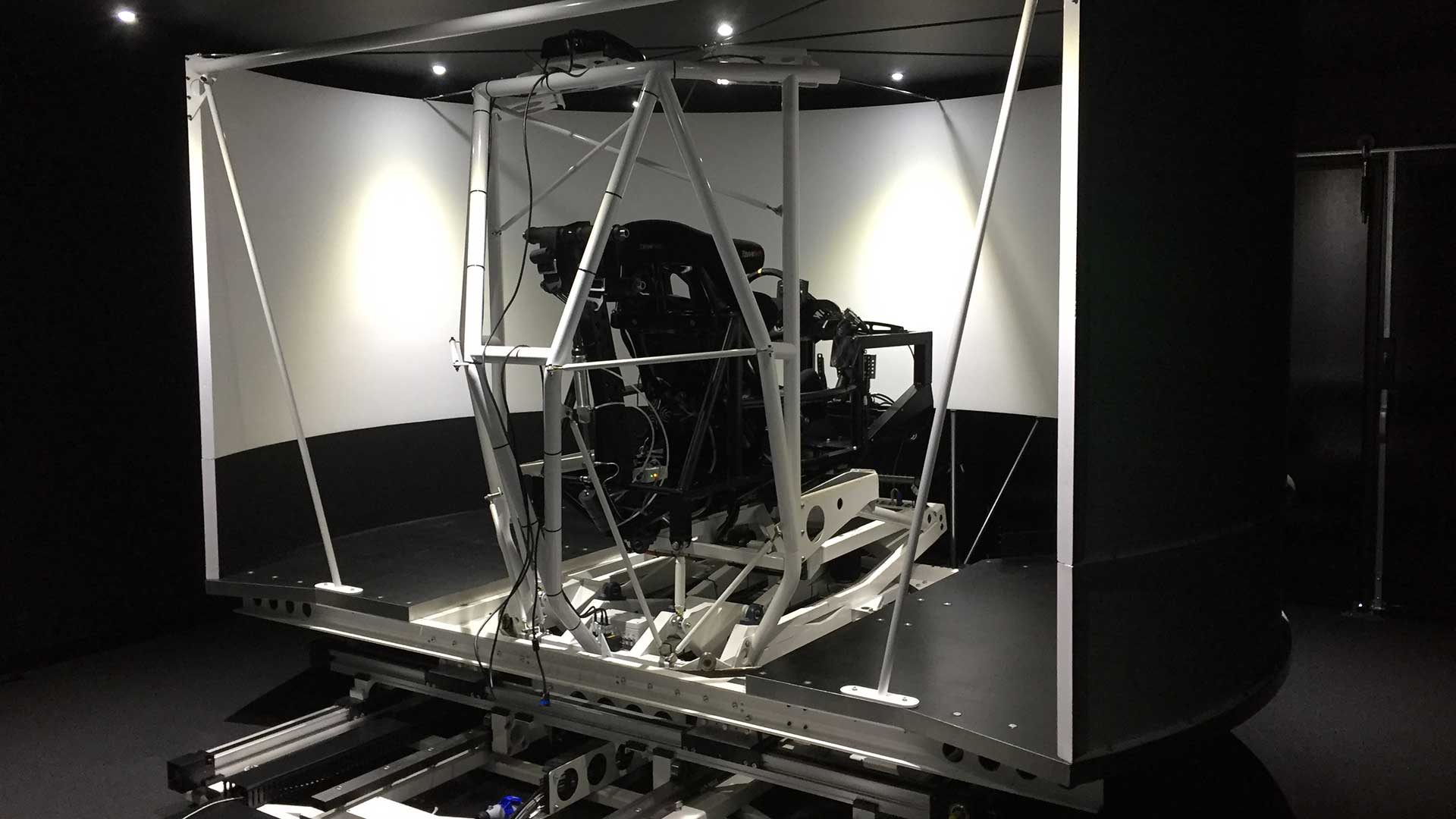

The Multimatic Vehicle Dynamics Centre (VDC) houses an industry-leading multi-post rig, Kinematics & Compliance (K&C) rig, and driver in the loop simulator (DiL), all under one roof. Our engineering staff to guide you through all three facilities, guaranteeing continuity for your development project.

Using data obtained from the multi-post and K&C rig, an engineer can make informed decisions knowing exactly what their car is doing on the road or on the track, allowing for faster and easier design and set-up decisions to improve ride and handling.

Data from the multi-post and K&C rigs can also help correlate accurate offline and driver-in-loop vehicle models. Thanks to Multimatic’s simulation expertise, its engineers can design test programmes to ensure you have the data required for the best possible correlation. Alternatively, Multimatic can create vehicle models from this data that can be used in offline simulation and on our in-house DiL.

Our DiL is a six-degree of freedom platform with optional VR implementation, providing an immersive experience for the driver. Custom cueing routines allow changes to be subjectively evaluated from both a ride and handling perspective. Live telemetry allows for the real time objective analysis of data.

Analytics

Use of the K&C rig, multi-post rig, or DiL allows set-up sensitivities to be identified, which means that engineers can make set-up changes faster, safe in the knowledge that the changes will have the desired effect.

Optimisation

Work With Multimatic

Multimatic is a privately held, global enterprise supplying engineered components, systems, and services to the automotive and motorsports industries. Visit the careers page to find out more.